Image 1 of 9

Image 1 of 9

Image 2 of 9

Image 2 of 9

Image 3 of 9

Image 3 of 9

Image 4 of 9

Image 4 of 9

Image 5 of 9

Image 5 of 9

Image 6 of 9

Image 6 of 9

Image 7 of 9

Image 7 of 9

Image 8 of 9

Image 8 of 9

Image 9 of 9

Image 9 of 9

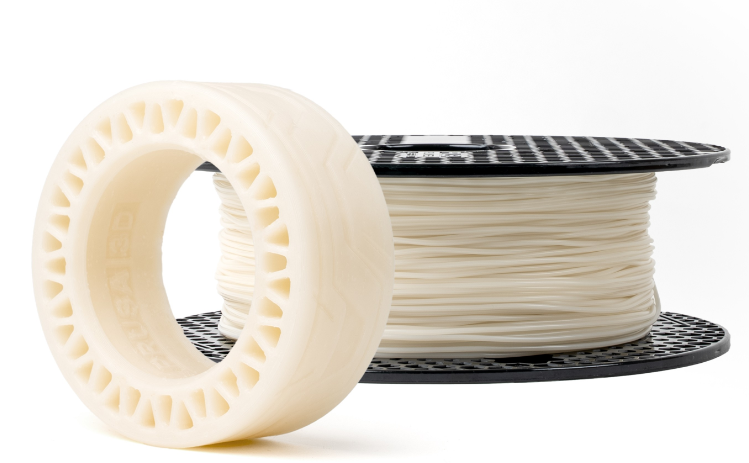

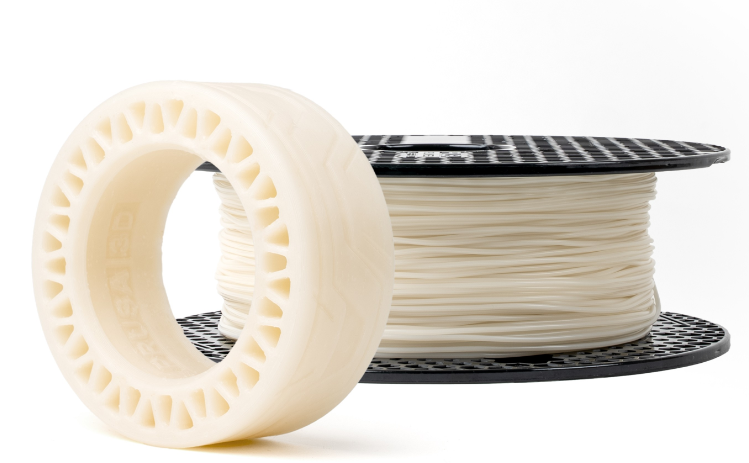

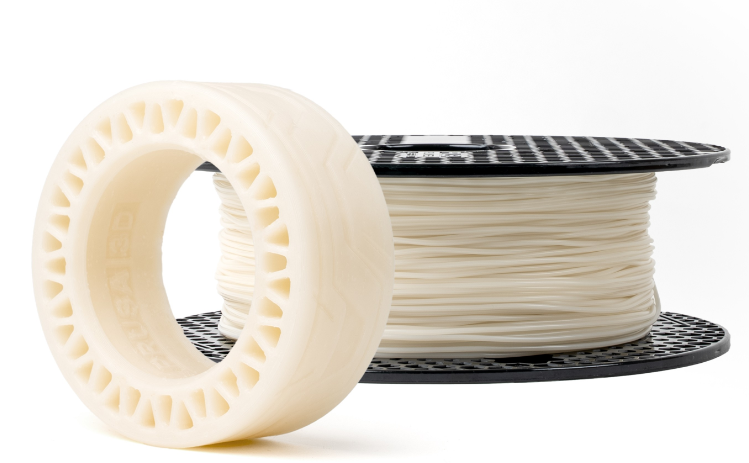

Prusament TPU 95A Natural 500g

Please note this item is Pre Order - 10 to 14 working days

Prusament TPU 95A is our own in-house made filament. The whole manufacturing process is closely monitored and tested - we guarantee ±0.06 mm precision and highly consistent color. You can inspect the parameters of every spool we made at prusament.com. Check the sample spool!

You can inspect the parameters of every spool we made at prusament.com. Check the sample spool!

Manufactured In-House By Josef Prusa

Premium-Grade Materials And Thorough Testing

The whole manufacturing process is closely monitored and tested – string diameter, color consistency, and mechanical properties – to make sure that every spool is perfect.

± 0.06 mm Manufacturing Guaranteed Precision

Many manufacturers sell TPU with a less precise and consistent diameter than they claim. Prusa guarantee ±0.06mm precision and highly consistent colors in our filaments.

High Quality You Can Check Yourself

We are the only manufacturer that gives the option to inspect parameters of every filament spool. Scan a QR code on the spool to see all details online (check the sample spool).

More about TPU 95A

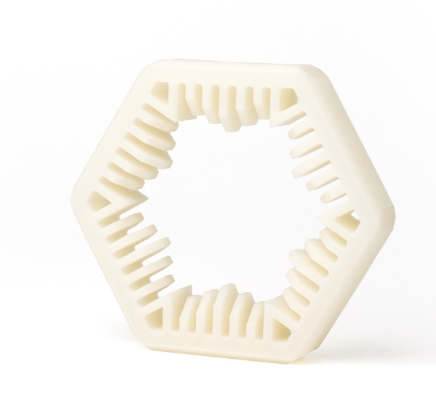

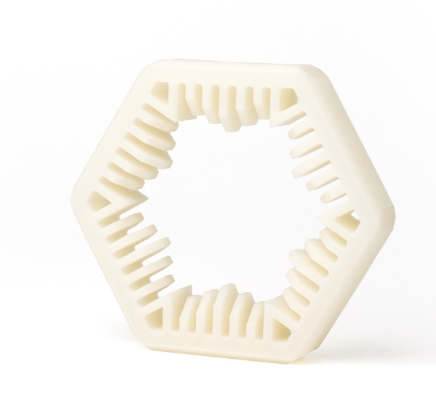

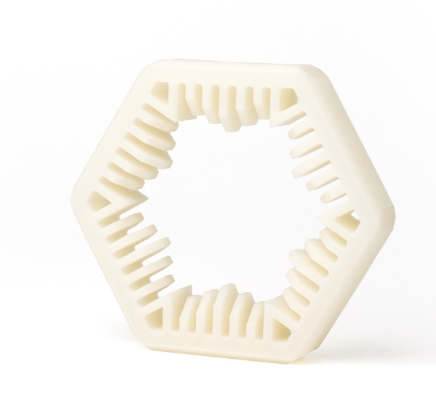

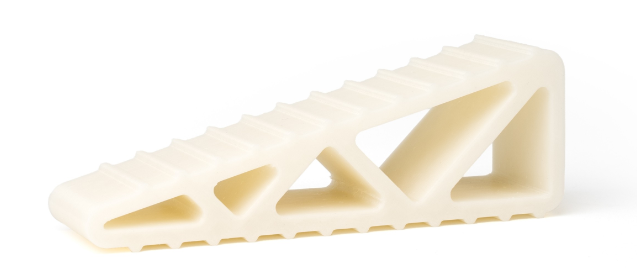

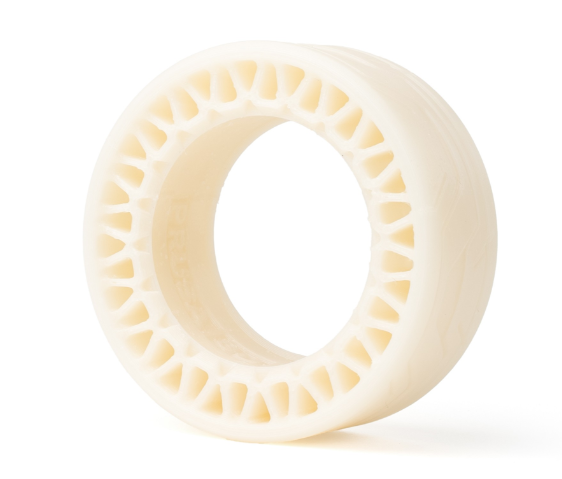

Prusament TPU 95A is a durable material with flexible properties and extreme wear resistance. It offers a precise and consistent diameter, which is by far not a common thing among flexible filaments. The Prusament TPU 95A polymer structure (ether diol type) slightly differs from most TPU filaments (ester diol type). This difference gives this material several advantages in both mechanical and chemical resistance. The Prusament TPU 95A offers very low moisture absorption and high hydrolysis resistance. Its high elasticity and impact resistance remain even at low temperatures (as low as -50 °C). Also, this material is resistant to microbial degradation, comes with good temperature resistance (HDT 78.6 °C at 1.80 MPa), and great chemical resistance (mostly to oil and grease).

Printing Setup

Nozzle 230±10°C

Heatbed 65±10 °C

Recommended Steel Sheet/PA Nylon / Satin

Before printing, learn about print surface preparation in our dedicated article and material table.

Basic Attributes

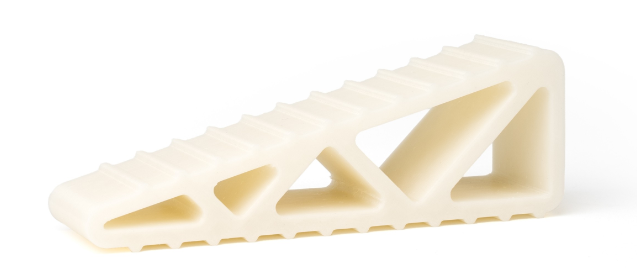

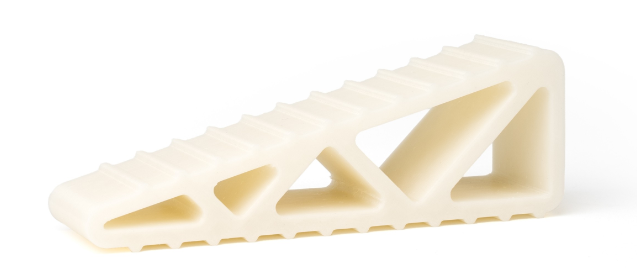

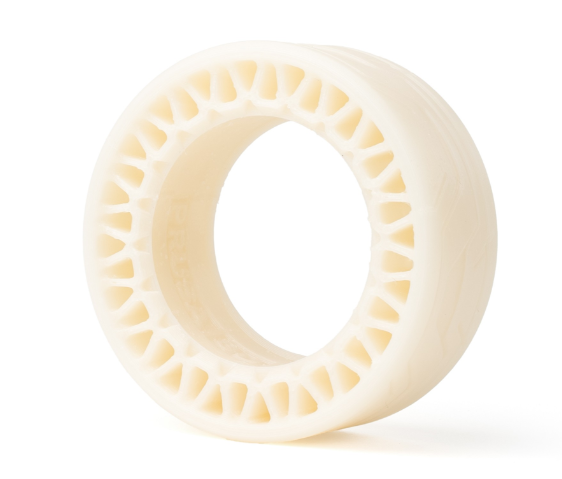

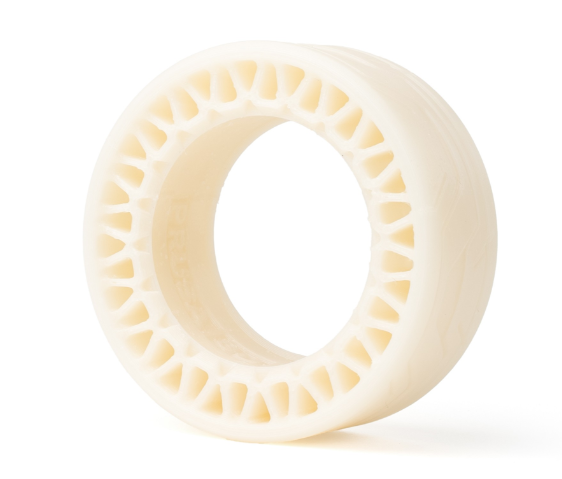

Soft and bendable at thin layers, strong and durable at thick layers

High print reliability with little to no stringing

Precise diameter

Good at printing bridges and overhangs (compared with other TPUs)

Great wear resistance

Flexible and durable at sub-zero temperatures

High resistance to hydrolysis and microbial degradation

Some extra tweaking before printing may be required (depending on your printer)

Printing with a smooth sheet requires a separation layer

Drying may be necessary when stored in high-moisture conditions

Large prints tend to warp

New spools equipped with OpenPrintTag

Prusament filaments are wound on a redesigned spool that introduces several improvements for an even better printing experience, starting in October 2025. The new spool features a simple locking mechanism that makes disassembly quick and easy, allowing effortless refills. It also stays secure during filament drying, even at higher temperatures. And with its slimmer dimensions, the spool ensures compatibility with a wide range of multi-color and multi-material printing systems.

Every new Prusament spool now comes with a fully rewritable NFC tag powered by the OpenPrintTag standard. It’s designed to work across brands and ecosystems. It is free to use, free to extend, and open for anyone to build upon. Most importantly, it works entirely offline. All essential data is stored directly on the tag. Your printer can recognize the spool instantly, with no dependence on cloud services or vendor lock-ins. The OpenPrintTag attached to your Prusament spool contains essential data about the material and can be read with the Prusa mobile app.

Beginners tips & tricks

Don’t print TPU directly on the smooth PEI sheet to prevent damage. We recommend using Satin or PA Nylon sheet instead. If you need to use a smooth sheet anyway, don’t forget to apply a separation layer onto it.

Sometimes you may encounter some stringing – this is usually caused by long storage in a humid area. Dry the filament as described in our online Help article, then store it in a drybox. Some of the stringing can be removed during the postprocessing with a lighter or a heat gun.

In thin layers with low infill, TPU is very soft and flexible. In thick layers, it becomes strong and virtually indestructible. If you want to print soft parts, use less dense gyroid infill. If you need durable and wear-resistant parts, try printing with more perimeters and high infill.

Notes

This TPU 95A was made in-house at Prusa Research.

This 1.75mm filament has a manufacturing tolerance of ± 0.06 mm.

Before printing, make sure the surface of the heatbed is clean as described in the 3D Printing Handbook.

Learn more about TPU 95A and how it was made in Prusas announcement blog article.

To dry the filament, please follow the instructions in this article.

Downloads

Please note this item is Pre Order - 10 to 14 working days

Prusament TPU 95A is our own in-house made filament. The whole manufacturing process is closely monitored and tested - we guarantee ±0.06 mm precision and highly consistent color. You can inspect the parameters of every spool we made at prusament.com. Check the sample spool!

You can inspect the parameters of every spool we made at prusament.com. Check the sample spool!

Manufactured In-House By Josef Prusa

Premium-Grade Materials And Thorough Testing

The whole manufacturing process is closely monitored and tested – string diameter, color consistency, and mechanical properties – to make sure that every spool is perfect.

± 0.06 mm Manufacturing Guaranteed Precision

Many manufacturers sell TPU with a less precise and consistent diameter than they claim. Prusa guarantee ±0.06mm precision and highly consistent colors in our filaments.

High Quality You Can Check Yourself

We are the only manufacturer that gives the option to inspect parameters of every filament spool. Scan a QR code on the spool to see all details online (check the sample spool).

More about TPU 95A

Prusament TPU 95A is a durable material with flexible properties and extreme wear resistance. It offers a precise and consistent diameter, which is by far not a common thing among flexible filaments. The Prusament TPU 95A polymer structure (ether diol type) slightly differs from most TPU filaments (ester diol type). This difference gives this material several advantages in both mechanical and chemical resistance. The Prusament TPU 95A offers very low moisture absorption and high hydrolysis resistance. Its high elasticity and impact resistance remain even at low temperatures (as low as -50 °C). Also, this material is resistant to microbial degradation, comes with good temperature resistance (HDT 78.6 °C at 1.80 MPa), and great chemical resistance (mostly to oil and grease).

Printing Setup

Nozzle 230±10°C

Heatbed 65±10 °C

Recommended Steel Sheet/PA Nylon / Satin

Before printing, learn about print surface preparation in our dedicated article and material table.

Basic Attributes

Soft and bendable at thin layers, strong and durable at thick layers

High print reliability with little to no stringing

Precise diameter

Good at printing bridges and overhangs (compared with other TPUs)

Great wear resistance

Flexible and durable at sub-zero temperatures

High resistance to hydrolysis and microbial degradation

Some extra tweaking before printing may be required (depending on your printer)

Printing with a smooth sheet requires a separation layer

Drying may be necessary when stored in high-moisture conditions

Large prints tend to warp

New spools equipped with OpenPrintTag

Prusament filaments are wound on a redesigned spool that introduces several improvements for an even better printing experience, starting in October 2025. The new spool features a simple locking mechanism that makes disassembly quick and easy, allowing effortless refills. It also stays secure during filament drying, even at higher temperatures. And with its slimmer dimensions, the spool ensures compatibility with a wide range of multi-color and multi-material printing systems.

Every new Prusament spool now comes with a fully rewritable NFC tag powered by the OpenPrintTag standard. It’s designed to work across brands and ecosystems. It is free to use, free to extend, and open for anyone to build upon. Most importantly, it works entirely offline. All essential data is stored directly on the tag. Your printer can recognize the spool instantly, with no dependence on cloud services or vendor lock-ins. The OpenPrintTag attached to your Prusament spool contains essential data about the material and can be read with the Prusa mobile app.

Beginners tips & tricks

Don’t print TPU directly on the smooth PEI sheet to prevent damage. We recommend using Satin or PA Nylon sheet instead. If you need to use a smooth sheet anyway, don’t forget to apply a separation layer onto it.

Sometimes you may encounter some stringing – this is usually caused by long storage in a humid area. Dry the filament as described in our online Help article, then store it in a drybox. Some of the stringing can be removed during the postprocessing with a lighter or a heat gun.

In thin layers with low infill, TPU is very soft and flexible. In thick layers, it becomes strong and virtually indestructible. If you want to print soft parts, use less dense gyroid infill. If you need durable and wear-resistant parts, try printing with more perimeters and high infill.

Notes

This TPU 95A was made in-house at Prusa Research.

This 1.75mm filament has a manufacturing tolerance of ± 0.06 mm.

Before printing, make sure the surface of the heatbed is clean as described in the 3D Printing Handbook.

Learn more about TPU 95A and how it was made in Prusas announcement blog article.

To dry the filament, please follow the instructions in this article.