Image 1 of 4

Image 1 of 4

Image 2 of 4

Image 2 of 4

Image 3 of 4

Image 3 of 4

Image 4 of 4

Image 4 of 4

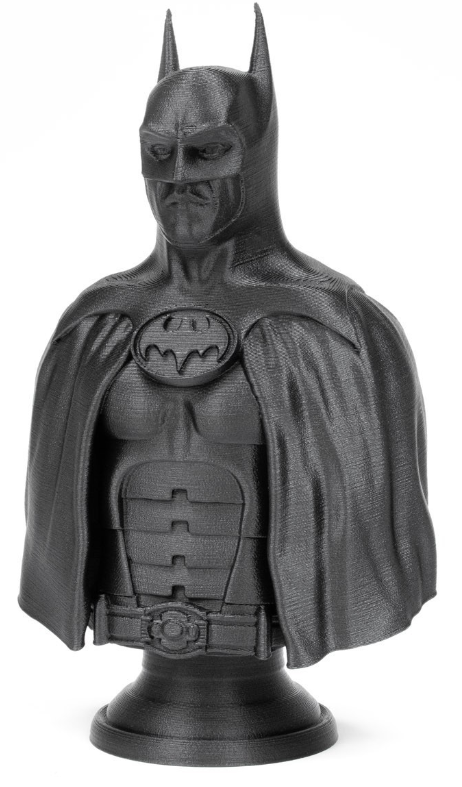

Prusament PA11 Carbon Fibre Black 800g NFC - PRE ORDER

£152.00

Get notified by email when this product is in stock.