Image 1 of 1

Image 1 of 1

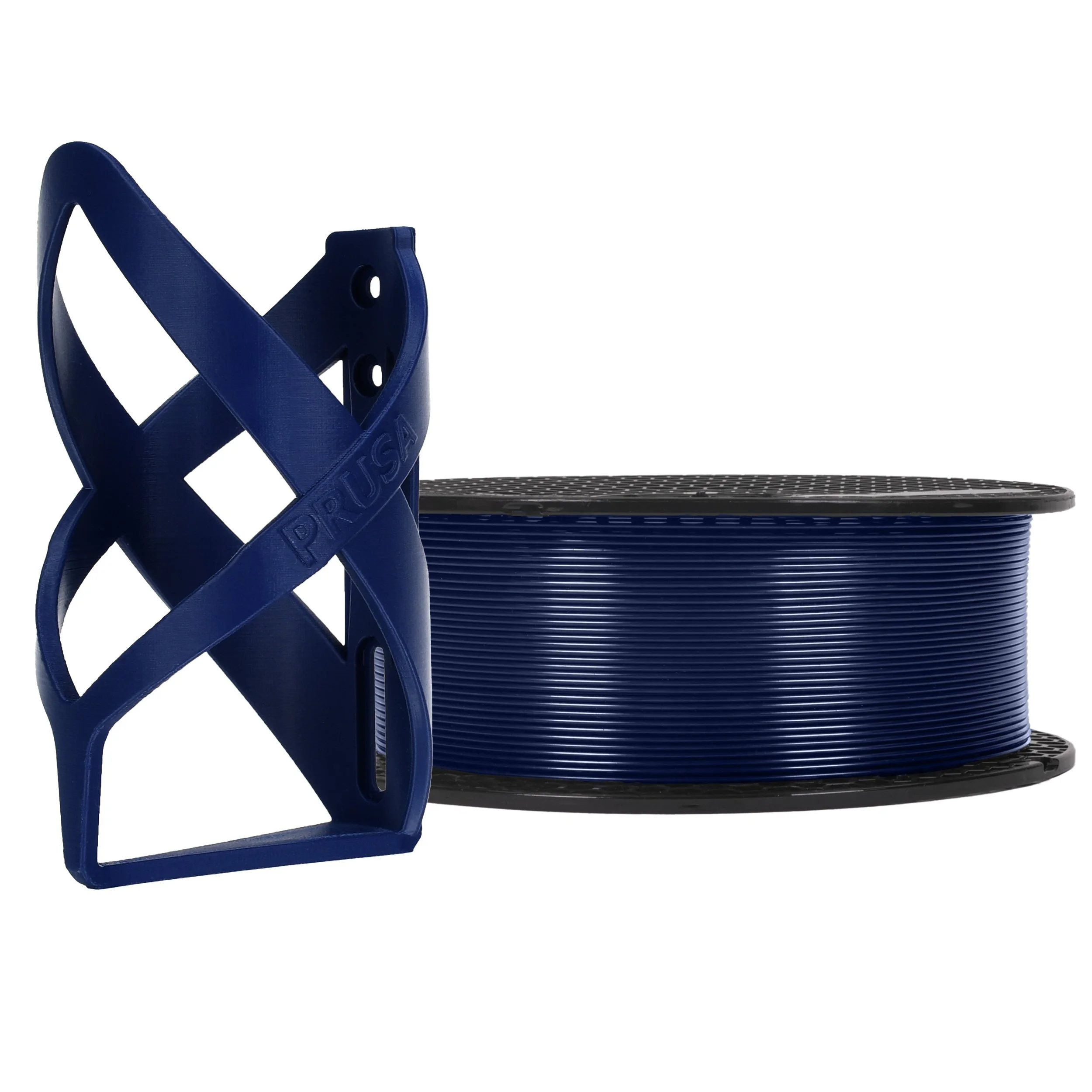

Prusament ASA Natural 850g

In stock

About ASA

ASA is a technical material with properties similar to ABS but better in several ways. Compared to ABS, it’s UV stable, it doesn’t suffer from shrinking so badly and the fumes produced are much less noticeable. ASA 3D prints are durable, tough and suitable for a wide range of applications. ASA comes with much better high-temperature resistance than other common materials, such as PLA or PETG. It shows no signs of deformation up to temperatures near 93 °C. Thanks to all these properties, ASA is especially suitable for printing objects meant for long-time outside use.

Printing Setup

Nozzle 260±5 °C

Heatbed 110±5 °C

Recommended Steel Sheet Satin

Basic Attributes

+Great for outside use (UV stable)

+Good high-temperature resistance

+Detailed prints without a stringing effect

+Can be smoothed with acetone vapours

+Can be easily sanded / post-processed

+Good mechanical resistance

-Large models have a tendency to warp

-Produces a slight odour of burned plastic during printing (less than ABS)

-Requires enclosure

-Contains styrene (potentially harmful fumes)

-Slightly hygroscopic (absorbs moisture)

Beginners tips & tricks

You may encounter some issues related to shrinking (warping) of the material – especially when printing larger models. This effect is much less severe compared to ABS but still, even with the heatbed set to 110°C, the prints can shrink and warp, causing them to detach from the print bed. This issue can be eliminated by printing inside an enclosure (for example our Prusa Enclosure) or by adding a draft shield around the object.

It’s important to run the prints in a well-ventilated room because the material releases fumes and substances that could pose a potential health risk. When ventilating the room, do not create a draft around the print – this will negatively impact the result.

Notes

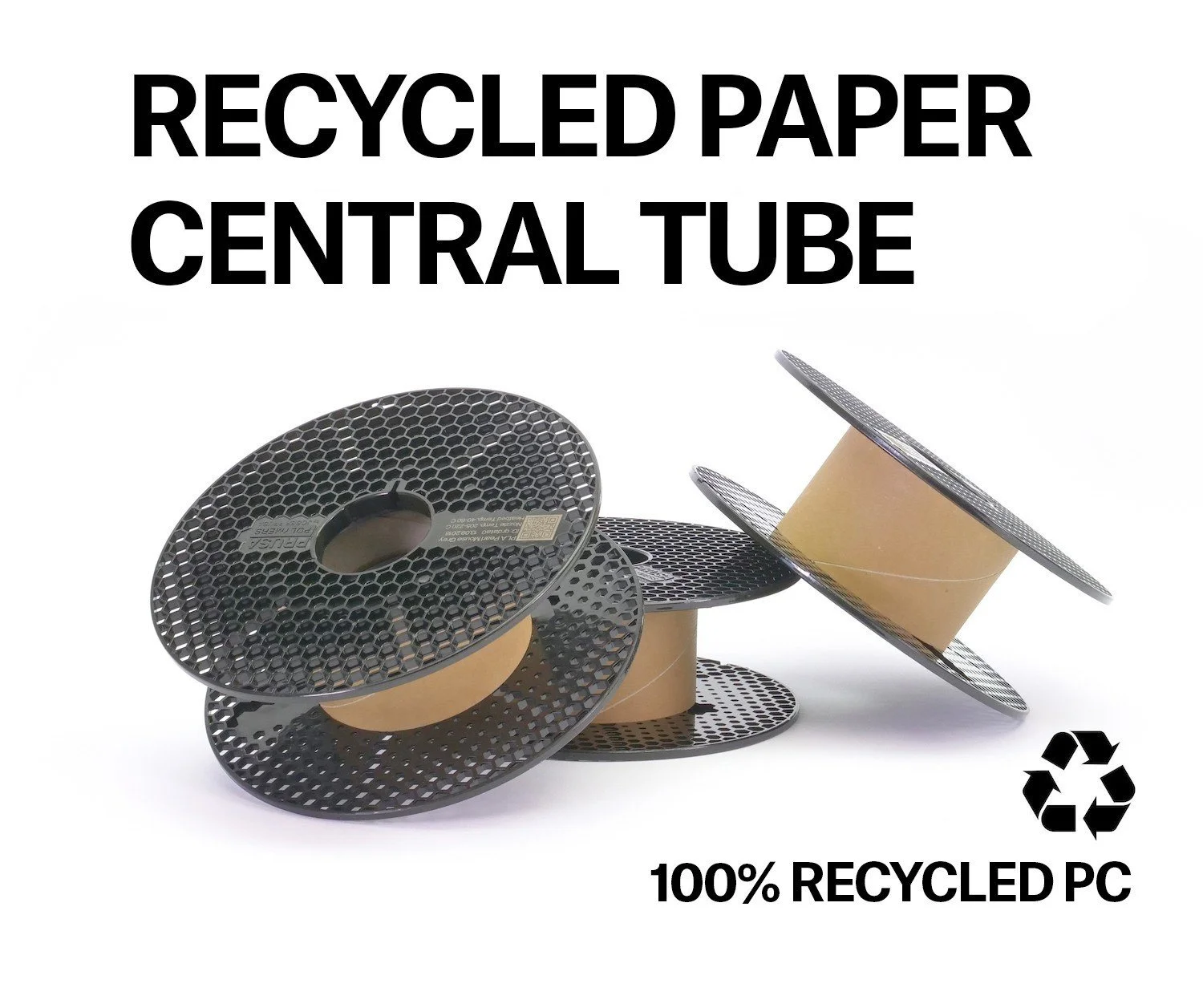

This ASA is made in-house by Prusa Research.

Starting from May 2024, all Prusament ASA spools have a tolerance of +- 0.04 mm instead of 0.03 due to changes to the manufacturing process.

Before printing, make sure the surface of the heatbed is clean as described in 3D Printing Handbook.

To dry the filament, please follow the instructions.

In stock

About ASA

ASA is a technical material with properties similar to ABS but better in several ways. Compared to ABS, it’s UV stable, it doesn’t suffer from shrinking so badly and the fumes produced are much less noticeable. ASA 3D prints are durable, tough and suitable for a wide range of applications. ASA comes with much better high-temperature resistance than other common materials, such as PLA or PETG. It shows no signs of deformation up to temperatures near 93 °C. Thanks to all these properties, ASA is especially suitable for printing objects meant for long-time outside use.

Printing Setup

Nozzle 260±5 °C

Heatbed 110±5 °C

Recommended Steel Sheet Satin

Basic Attributes

+Great for outside use (UV stable)

+Good high-temperature resistance

+Detailed prints without a stringing effect

+Can be smoothed with acetone vapours

+Can be easily sanded / post-processed

+Good mechanical resistance

-Large models have a tendency to warp

-Produces a slight odour of burned plastic during printing (less than ABS)

-Requires enclosure

-Contains styrene (potentially harmful fumes)

-Slightly hygroscopic (absorbs moisture)

Beginners tips & tricks

You may encounter some issues related to shrinking (warping) of the material – especially when printing larger models. This effect is much less severe compared to ABS but still, even with the heatbed set to 110°C, the prints can shrink and warp, causing them to detach from the print bed. This issue can be eliminated by printing inside an enclosure (for example our Prusa Enclosure) or by adding a draft shield around the object.

It’s important to run the prints in a well-ventilated room because the material releases fumes and substances that could pose a potential health risk. When ventilating the room, do not create a draft around the print – this will negatively impact the result.

Notes

This ASA is made in-house by Prusa Research.

Starting from May 2024, all Prusament ASA spools have a tolerance of +- 0.04 mm instead of 0.03 due to changes to the manufacturing process.

Before printing, make sure the surface of the heatbed is clean as described in 3D Printing Handbook.

To dry the filament, please follow the instructions.